The price of palladium has, for the most part, been on a steady decline since its peak while prices and supply of spent gasoline catalytic converters remained erratic. As more scrap converters buyers are turning their attention to diesel catalytic converters, it helps to have a better understanding of how they differ from their gasoline counterparts in composition and operation as well as how they affect the recycle value.

Focusing specifically on diesel catalytic converters, which differ from their gasoline counterparts in both composition and operation due to the different nature of diesel exhaust emissions, let’s take a closer look.

Understanding Diesel Catalytic Converters

Function: They reduce the emission of particulate matter, nitrogen oxides (NOx), and hydrocarbons (HC) from diesel engines. Unlike gasoline converters, they often include a diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF) alongside NOx reduction systems like selective catalytic reduction (SCR).

Composition: Contains precious metals such as platinum and sometimes palladium, but in different proportions compared to gasoline converters. There’s usually no Rhodium in diesel auto-catalysts. This is because Rhodium is ineffective in reducing NOx in diesel exhaust due to its high oxygen content. The presence of a DPF, which traps soot particles, is unique to diesel systems.

Components:

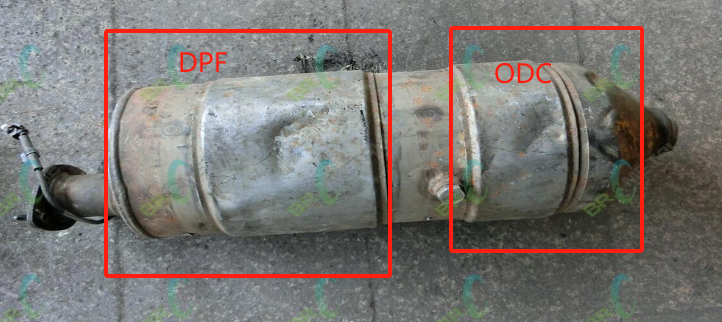

For diesel cars, the auto catalyst system usually comprises 2 components – the Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF). Most such diesel systems reduce NOx in a process called Exhaust Gas Re-circulation, and this process doesn’t require a Selective Catalytic Reduction (SCR) catalyst.

Diesel Oxidation Catalyst (DOC)

You will find a Diesel Oxidation Catalyst (DOC) in every diesel system. It is a critical component that converts poisonous carbon monoxide into carbon dioxide and break down any residual fuel. This component of the diesel catalyst system operates similarly to its counterpart in gasoline engines. Despite being the most compact part of a diesel converter, the DOC holds the greatest recycling value due to its concentration of platinum and palladium. Typically, it is located at the head of the exhaust system.

Diesel Particulate Filter (DPF)

The Diesel Particulate Filter (DPF) is engineered to trap particulate, or soot emitted by diesel engines. This trapped soot is then burned off during a cleaning process called “regeneration”. During regeneration, the trapped organic matter is oxidized into carbon dioxide and water. There are small amounts of platinum and palladium in the DPF to catalyse this process.

Selective Catalytic Reduction (SCR)

Some diesel trucks and lorries have an additional component in their exhaust system called the Selective Catalytic Reduction (SCR) catalyst. The SCR catalyst can be found after the DOC as indicated in the photo above, and it is usually the biggest of the three components that made up the exhaust system. However, it has little or no recycling value.

Diesel Converters Recycling Process

- Collection: Diesel catalytic converters are collected from our customers, scrapyards, auto mechanics, etc

- Identification and Sorting: Given the variety of diesel converter types, including those with integrated DPFs, identification and sorting are crucial for determining the price and recycling process. We have an online catalogue with more than 20,000 of different make and model of converters from both gasoline and diesel vehicles, providing accurate breakdown of Platinum Group Metals content and prices.

- Decanning: The converters are opened to access the ceramic or metallic honeycomb structure that contains the precious metals.

- Crushing and Milling: The material is then crushed and milled into a fine powder using our patented sampling system proven to reduce wastage by at least 6%. This step is especially important for DPFs, which can contain a significant amount of platinum.

- Sampling and Analysis: Detailed chemical analysis is performed to identify the precise content of precious metals, so that we can hedge the precious metals and pay our customers for what their converters are truly worth.

- Refining & Metal Extraction: The homogenised materials are sent to our partner refineries, where precious metals will be extracted and then refined to achieve the purity required for their reuse in various industries, including the production of new catalytic converters.

Specific Considerations for Diesel Converters Recycling

– DPF Recycling: The process for recycling diesel particulate filters, integrated within many diesel converters, involves additional steps to recover the platinum used to coat the filter.

– Expert Knowledge: Diesel converters come from a wide range of vehicles including personal, commercial, and industrial. You need a partner with the depth and breath of experience in recycling diesel catalytic converters to help you with distinguish different make and model, provide insight into which are the most valuable models to recycle based on the amount of precious metals contained within, and how to spot the difference between components with high recycling value like DOC and SCR units. We will also provide pricing APP for long-time partner so that they don’t overpay for diesel converter scraps in this volatile bear market.

These are the value-add services we provide to our partners so that they can maximise their recycling returns and value.

– Regulatory Compliance: Diesel catalytic converters, particularly those with DPFs, are subject to stringent regulations due to the toxic nature of some of the particulates they trap.

– Market Demand: The demand for Platinum Group Metals (PGM), especially platinum, from diesel converters, influences the economics of recycling. This market is subject to fluctuations based on automotive industry trends and the push towards cleaner energy sources. We are here to help our partner navigate the market uncertainties with timely insights and risk management strategies.

Recycling diesel catalytic converters combines environmental benefits with economic incentives, driven by the value of the recovered precious metals and the importance of reducing emissions from diesel engines. BR Metals is here to help you succeed!