BR Metals is an industry-leading specialist in the recycling of Platinum Group Metals (PGM) and one of Asia’s largest processors of end-of-life catalytic converters, an emission-control device found in both gasoline and diesel vehicles.

Established in 2009, our core competency has been the recovery of Platinum Group Metals (PGM). Our commitment to achieving the highest levels in recycling management, recovery outcome and customer satisfaction made us one of the largest processors of end-of-life catalytic converters, diesel particulate filters (DPF), industrial catalysts and other scraps containing PGM. As part of the global PGM supply chain, we reclaim and return an estimated 3 tons of Platinum, Palladium and Rhodium annually to the Circular Economy.

We are now taking the expert knowledge we have developed from the PGM sector and expanding into gold and silver recycling for different waste streams and industry sectors with the same level of transparency, analytical accuracy and quality assurance.

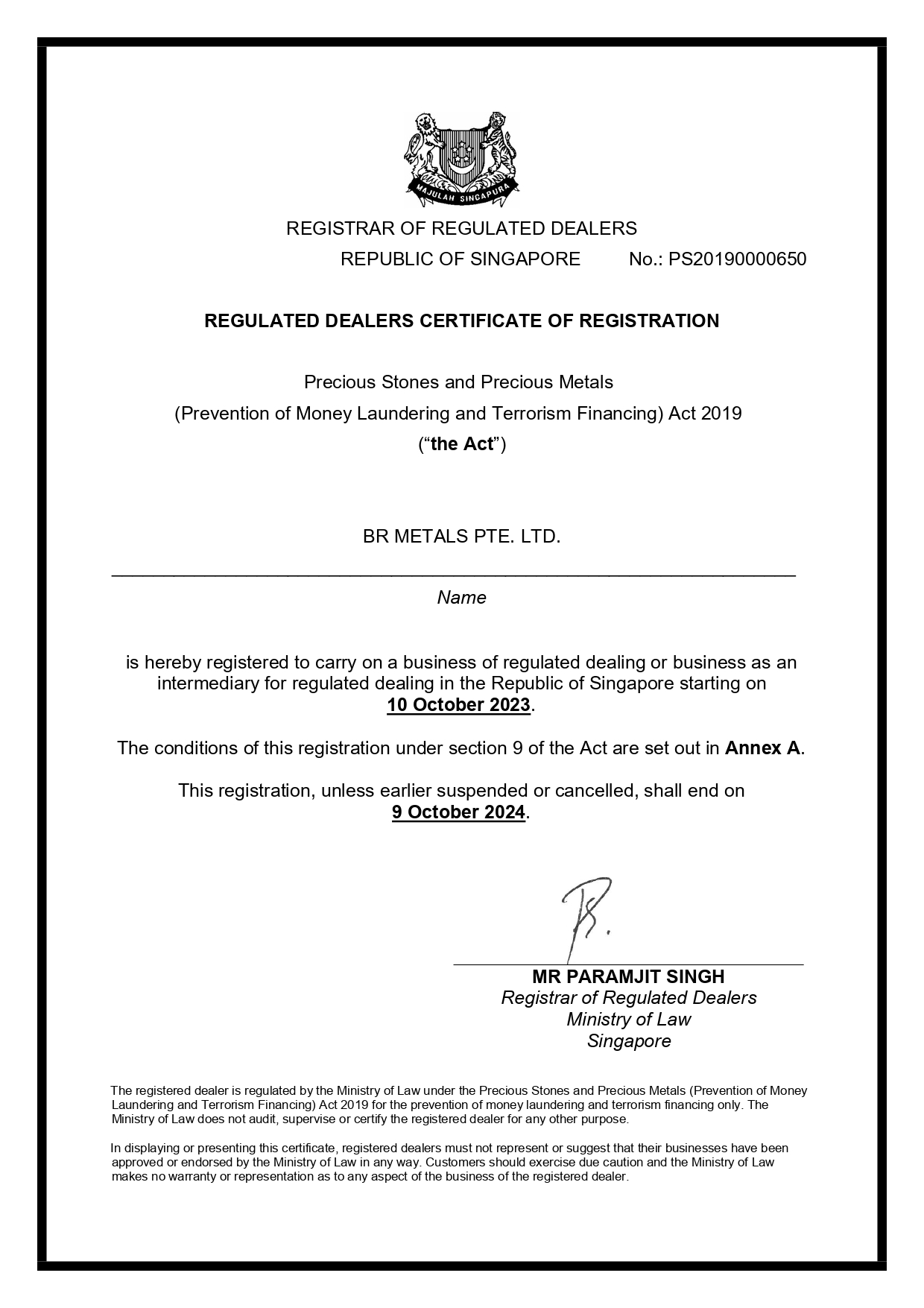

BR Metals has met the stringent requirements to be a licensed precious metals trader regulated by the Singapore Ministry of Law. We are also proud to be a member of Singapore Bullion Market Association (SMBA) upon fulfilling the rigorous application criteria.

As a leader in platinum group metals recovery, BR Metals strives to set high standards as a trusted partner and environmental vanguard that provides responsive services whilst observing all environmental, health and safety regulations.

BR Metals is committed to contribute to our customers’ growth through flexible arrangement, fair and transparent trading. To deliver superior client experience, we build a strong culture based on our CARE value system:

We seek to understand and excel in meeting customers’ needs.

We are proactive in problem-solving and creating value for clients and stakeholders. and recovery of earth’s renewable resources.

We are professional and take responsibility to ensure customer.

We strive for high performance in our work and services.

BR Metals is an industry-leading specialist in the recycling of Platinum Group Metals (PGM) and one of Asia’s largest processors of end-of-life catalytic converters, an emission-control device found in both gasoline and diesel vehicles.

Founded in 2009 to provide a sustainable and efficient alternative to deep-earth mining, the company now recovers 80,000 troy ounces of PGM annually from spent materials like catalytic converters, diesel particulate filters (DPF), spark plugs, oxygen sensors, industrial catalysts and automotive electronic control units and returns it to the circular economy.

We also go the extra mile to make selling and recycling your scrap a fuss-free experience. For every stage of your transaction, from preparing a customised offer that is aligned with your business goals, to transportation, cutting and sampling, through to the analysis and trading of the recovered metals, we have all the expertise in-house and will ensure all your needs are met in a timely manner.

To meet changing market dynamics, we are extending our focus beyond catalytic converter recycling and expanding our service offerings to include precious metals trading and the recycling of other materials.

BR Metals is committed to contribute to our customers’ growth through flexible arrangement, fair and transparent trading. To deliver superior client experience, we build a strong culture based on our CARE value system:

We are also committed to ensuring a safe and healthy workplace environment for all our staff. Our processing facility in Singapore is certified bizSAFE level 3 by the Singapore Workplace Safety and Health Council.

We are also committed to ensuring a safe and healthy workplace environment for all our staff. Our processing facility in Singapore is certified bizSAFE level 3 by the Singapore Workplace Safety and Health Council.